What is 1200 alloy aluminum foil? 1200 alloy aluminum foil for industrial pure aluminum, plasticity, corrosion resistance, high electrical conductivity, and thermal conductivity, but low strength, heat treatment can not be strengthened, poor machinability. This is a high-strength aluminum material that can pass heat treatment, plastic strength under quenching and newly quenched states, and cold strength during s ...

What is aluminum foil for inner tank Aluminum foil for inner tank refers to a method of making inner tank, that is, aluminum foil material is used when making inner tank. A liner refers to a container, usually used for storing or cooking food. Aluminum foil is a thin, malleable metallic material made of aluminum alloy that is often used in food packaging and cooking utensils. The advantage of using aluminum f ...

What is medicinal aluminum foil Pharmaceutical aluminum foil is generally a thinner aluminum foil, and its thickness is usually between 0.02mm and 0.03mm. The main feature of pharmaceutical aluminum foil is that it has good oxygen barrier, moisture-proof, protection and fresh-keeping properties, which can effectively protect the quality and safety of medicines. In addition, pharmaceutical aluminum foil also h ...

Advantages and main applications of aluminum foil food packaging Aluminum foil food packaging is beautiful, lightweight, easy to process, and easy to recycle; aluminum foil packaging is safe, hygienic, and helps maintain the aroma of food. It can keep food fresh for a long time and provide protection from light, ultraviolet rays, grease, water vapor, oxygen and microorganisms. In addition, please be aware of th ...

What is house hold aluminium foil? Household Aluminium Foil ( HHF ) has many special characteristics: rich polish, lightweight, anti-damp, anti-pollute and is the well transmit electricity body. It has been used vastly in the shield layer of the food vessel, electron, material equipment, and communication cable. We can supply aluminum foil thickness from 0.0053-0.2mm, and width from 300-1400mm. Alloy includes 80 ...

what is 1145 alloy aluminum foil? 1145 alloy aluminum foil and its sister alloy 1235 have a minimum aluminum content of 99.45%, and the chemical and physical properties are almost the same. Occasionally, some production batches can be double-certified for 1145 and 1235 alloys. Like 1100 aluminum alloys, both are considered commercially pure alloys with excellent formability. Due to the high aluminum content, ...

Heavy duty aluminum foil and aluminum foil are both made of aluminum by rolling, and they have many similarities. The biggest difference between the two is the thickness, which also leads to differences in many aspects of performance. The main difference Ordinary aluminum foil: generally refers to aluminum foil with a thinner thickness and used for conventional packaging, protection and other purposes. Its ...

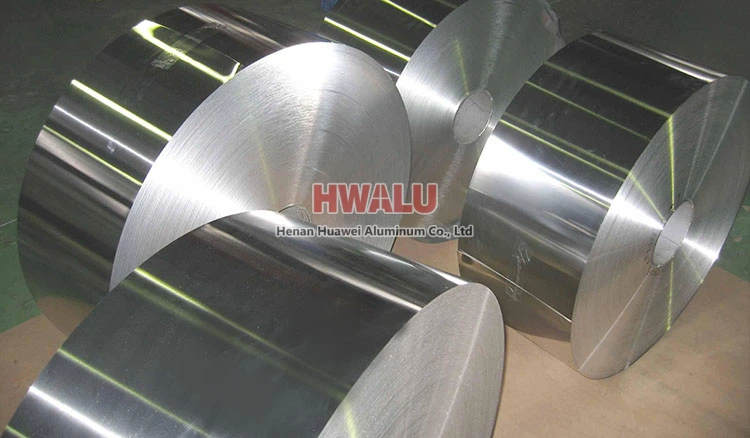

Coiling defects mainly refer to loose, layer channeling, tower shape, warping and so on. Aluminum foil roll during the winding process. Because the tension of aluminum foil is limited, enough tension is the condition to form a certain tension gradient. Therefore, the winding quality ultimately depends on good shape, reasonable process parameters and suitable precision sleeve. It is ideal to obtain tight coils ...

In the production process of aluminum foil, there are multiple processes such as rolling, finishing, annealing, packaging, etc. The interlocking production process, any problem in any link may cause aluminum foil quality problems. The quality defects of the purchased aluminum foil products will not only affect the appearance, but also directly affect the quality of the products produced, and even more directly ca ...

Is the aluminum foil in the oven toxic? Please pay attention to the difference between the oven and the microwave. They have different heating principles and different utensils. The oven is usually heated by electric heating wires or electric heating pipes. Microwave ovens rely on microwaves to heat. The oven heating tube is a heating element that can heat the air and food in the oven after the oven is pow ...

The performance differences between 3003 aluminum foil and aluminum plate are primarily related to its physical and mechanical properties and its intended application. Here are some of the main differences in performance: Formability: 3003 Aluminum Foil: 3003 aluminum foil is highly formable and can be bent, formed and folded easily. It is often used in applications that require flexibility and ease of mold ...

Aluminum foil plays a vital role in the construction of lithium-ion batteries. There are many models in the 1000-8000 series alloys that can be used in battery production. Pure aluminum foil: Pure aluminum foil commonly used in lithium batteries includes various alloy grades such as 1060, 1050, 1145, and 1235. These foils are usually in different states such as O, H14, H18, H24, H22. Especially alloy 1145. ...