What is aluminum foil for foil board Aluminum foil for foil board refers to a special type of aluminum foil used to make foil board, also known as "foil material". Foil sheets are commonly used to package food and pharmaceuticals to protect them from air, moisture, odours, light and other external elements. Aluminum foil for foil boards is usually thicker than regular aluminum foil, usually between 0.2-0.3 mm ...

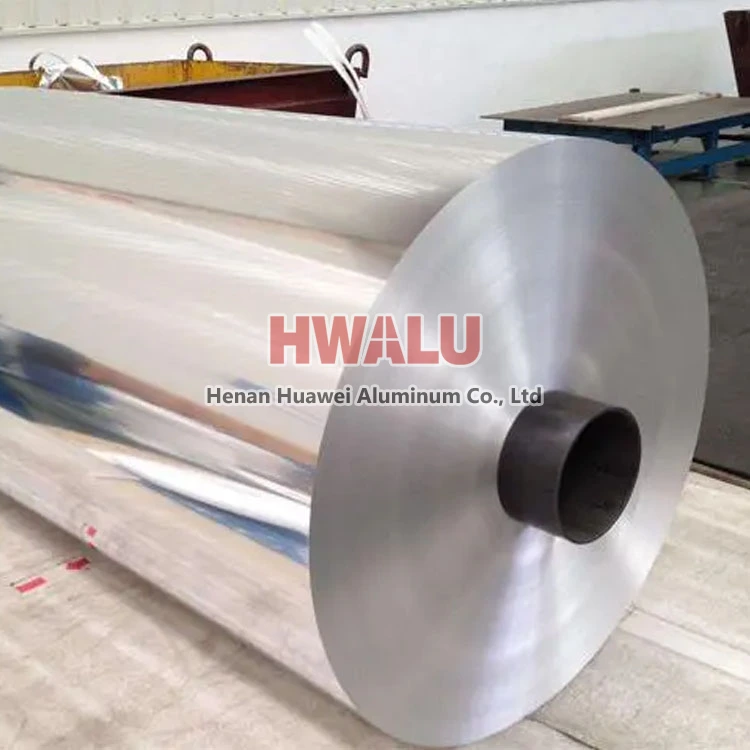

Introduction to industrial aluminum foil What is industrial aluminum foil? Aluminum foil is a kind of aluminum rolled material. Aluminum foil mainly refers to thickness. In the industry, aluminum products with a thickness of less than 0.2mm are usually called aluminum foil. They are usually cut longitudinally at the edges and delivered in rolls. Industrial aluminum foil, as the name suggests, is an aluminum foil ...

How to define light gauge aluminum foil? Light gauge aluminum foil usually refers to aluminum foil with a thickness of less than 0.01mm, that is, aluminum foil with a thickness of 0.0045mm~0.0075mm. 1mic=0.001mm Example: 6 mic aluminum foil, 5.3 mic aluminum foil Aluminum foil with thickness ≤40ltm can also be called "light gauge foil", and aluminum foil with thickness >40btm can be called "heavy gau ...

Aluminum foil for grills Aluminum foil for grilling is a versatile tool used in outdoor cooking. Grill foil is a thin, flexible sheet of aluminum that can be placed over your grill grates to aid in various aspects of grilling. Advantages of aluminum foil for barbecue packaging Aluminum foil is often used for barbecue packaging and has the following advantages: 1. Thermal conductivity: Aluminum foil has ...

Honeycomb Aluminium foil Details Typical alloy 3003 5052 Temper O,H14, H16, H22, H24, O、H12、H14、H16、H18、H19、H22、H24、H26 Thickness (mm) 0.005-0.2 0.03-0.2 Width (mm) 20-2000 20-2000 Length (mm) Customized Treatment mill finish payment method LC/TT what is Honeycomb aluminum foil? Honeycomb aluminum foil has the advantages of light weight, high strengt ...

Custom printing aluminum foil jumbo roll The printing process and precautions of aluminum foil for medicine packs The process flow of packaging aluminum foil is: aluminum foil unwinding -> gravure printing -> drying -> protective layer coating -> drying -> adhesive layer coating -> drying -> aluminum foil winding. In order to achieve the above-mentioned performance requirements in the PTP ...

Product name: industrial aluminum foil roll Item Specification (mm) Description ALUMINUM FOIL ROLLS WITH SUPPORT FOR INDUSTRIAL USE 8011-O, 0. 014 (+/-4%) *300 (+/-1mm). Outside -matt Inside - bright ID 152 OD min 450, Max 600. Elongation - min 2% Tensile strength - min 80, max 130MPa. Porosity - max 30 pcs per 1m2. Wettability - A. Splices - maximum 1 splice per ...

Foil winding, aluminum foil to be tensioned, in order to maintain a certain tension, smooth, flat winding coil, the thicker the aluminum foil requires greater tension, the maximum tension of the coil winding machine is limited, exceeding the maximum tension of the machine is dangerous, the tension is too small winding coil loose, can not ensure the size requirements. Therefore, here is not to say that you want to ...

What is the density of aluminum foil alloy? Aluminum foil is a hot stamping material that is directly rolled into sheets of metallic aluminum. Because the hot stamping effect of aluminum foil is similar to that of pure silver foil, aluminum foil is also called fake silver foil. Aluminum foil is soft, malleable, and has a silvery white luster. It also has a lighter texture, thanks to the lower density of aluminum ...

Since aluminum foil has shiny and matte sides, most of the resources found on search engines say this: When cooking food wrapped or covered with aluminum foil, the shiny side should face down, facing the food, and the dumb side Glossy side up. This is because the glossy surface is more reflective, so it reflects more radiant heat than matte, making the food easier to cook. Is it really? Let's analyze the heat ...

Color-coated aluminum foil is an aluminum foil material with a coated surface. By applying one or more layers of organic coatings or special functional coatings on the surface of the aluminum foil, the color-coated aluminum foil has the characteristics of diverse colors, beautiful and durable, and diverse functions. Color-coated aluminum foil has many product characteristics, beautiful, weather-resistant, durabl ...

In the production of double foil, the rolling of aluminum foil is divided into three processes: rough rolling, intermediate rolling, and finishing rolling. From a technological point of view, it can be roughly divided from the thickness of the rolling exit. The general method is that the exit thickness is greater than Or equal to 0.05mm is rough rolling, the exit thickness is between 0.013 and 0.05 is intermediat ...